Two young entrepreneurs based in the Songshan Lake Xbot Park have shown that with a lot of guts, and the ability to humbly shift direction quickly, success is possible in this promising industry.

Shifting the positioning

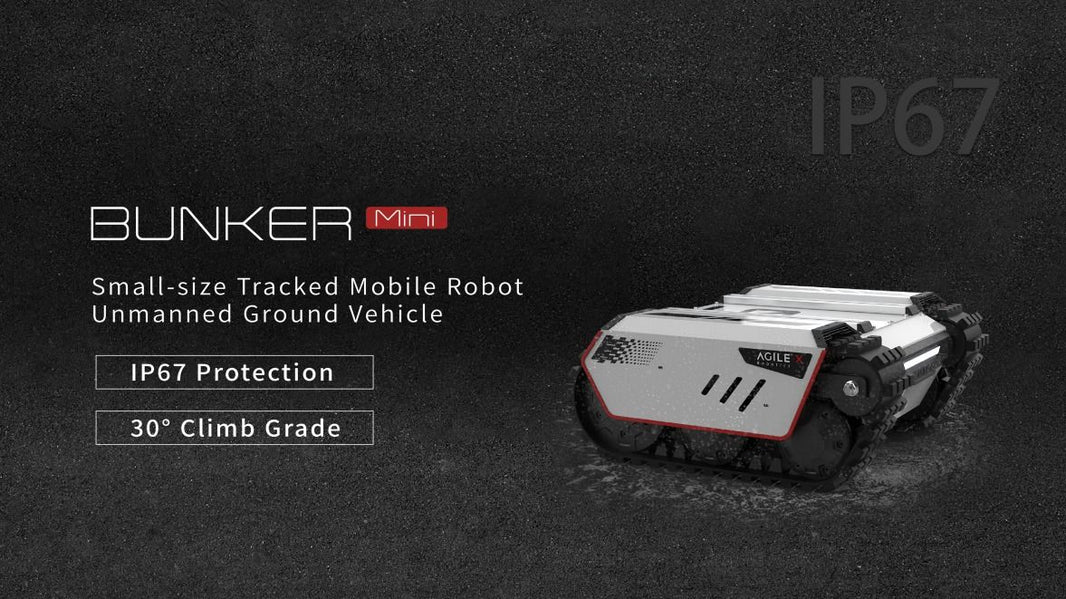

During its initial development in 2016-2018, the company put all its efforts into parking robots. It became what’s known in the tech industry as a “learning experience.” Although Wei and Jiang believed their initial idea was “life-changing”, the company had a hard time bringing the product to market. “August 28th, 2018, was the third anniversary of our company, but it was, in fact, the darkest moment for us,” says Wei, thinking back. “I knew we would run out of money in a few months and the investors were not responding well.” As CEO, he had to make a tough decision and accept the cruel reality: the product did not fit the market. “I wasn’t looking for new investment because I couldn’t persuade myself to take a product that I didn’t believe in to investors.” Looking back, Jiang believes he can see what went wrong more clearly. One reason was the limited environment. “Although our product sounded awesome, there were very few fully-automated smart parking lots that allowed for the adoption of our parking robot.” Another was the cost of cultivating user habits and developing a well-rounded support system. “This was not affordable for a start-up. It had to be done by at least a medium-sized enterprise.” It was like “having a small horse drag a heavy truck”, Wei concluded, recognizing that parking robots were not really what they were passionate about. “If you take a look at those successful tech companies today, the founders are usually their own first clients. For instance, the founder of DJI, Wang Tao, had been a huge fan of model airplanes since he was a student. But the parking robot was a whole new field for us.” Wei and Jiang shifted quickly to UGVs. Their thinking was based on three reasons, Jiang says. “Firstly, it’s something that sounds easy to make but is not so easy. Secondly, the product can be implemented in various industrial environments as a basic facility.” Jiang considered their “small unmanned vehicle” had to be “like rice” i.e. something essential that can go with a wide variety of “dishes”. Thirdly, production costs were much lower. AgileX’s UGVs are currently sold at tens of thousands of yuan, the most expensive being just over RMB100,000, whereas parking robots had carried a price tag of RMB700,000. “Lower prices gave us access to a wider market and we could get it to maturity in a shorter time.” The forerunner of Scout was a semi-finished product that Wei put together with an intern. “I just threw this product into a small circle of my acquaintances, and surprisingly, someone sent me a prepayment on the same day. More orders followed.” With RMB60,000 from the first version, Wei started to focus on an upgrade. “I had to let others handle the production. All I did during that time was try to sell like crazy.” The semi-finished “small vehicle” has now been upgraded to AgileX’s star product, Scout, which is a full-featured UGV. With an automatic chassis, wheels and general purpose interfaces, it is used for industrial purposes like spraying agricultural pesticides, inspection, and industrial logistics.

Survive first before getting innovative

Sales, needless to say, were welcome. The company can now afford to move on to mass production and is already selling 50-60 units of different models on average each month. Although AgileX mainly sells standardized products, the company also designs customized products for specific implementation environments, with clients such as consumer-goods behemoth P&G. “There are three levels of UGV business,” says Wei. “The first is a high-end remote-controlled vehicle. The second is to add GPS and all the unmanned features. And the third is the vehicle in a specific industrial environment.” Initially, Scout was intended for as wide a range of customers as possible. Features were carefully selected only to serve essential purposes that would be most commonly needed. Now, Wei points out, the current product aims to match the basic needs of both industrial and non-industrial clients. Instead of putting their eggs in different baskets, Wei emphasized the importance of focusing on only one product and to make it the best, which is essential for attracting customers to ensure the survival of a tech start-up. “I saw some companies who invest in two or three different products targeting different markets. But I only focused on one and made it the best in my targeted customer group.” Wei has a strong development team to give him confidence. All have previously participated in the Asia-Pacific Robot Contest, also known as ABU ROBOCON. Jiang was a member of a champion team when he was a college student. Both members of the post-1990s generation, Jiang believes the keyword of his generation is “change”, yet he also believes young people should learn the spirit of survival from those born in the 70s or 80s. “Wei always tells me stories about many entrepreneurs in Shenzhen who had to sleep under bridges when they were building their businesses from scratch. Many small enterprises established by the post-70s and post-80s generation are very resilient. They can survive for more than ten years with just a tiny production plant for a single product. This is much better than many start-ups nowadays.” Start-ups should aim to survive the first three years and earn “the first bucket of gold”; thereafter they can expand, Jiang says. Wei also stresses that survival capability is essential for a company to attract investment. “Nowadays, many investors who used to invest in ‘concept stocks’ feel insecure. They came to us because we can earn money and do things step by step. Investors are becoming more discrete and choosy these days.” The cooperation and strong bond of the two founders has also been essential for the company’s success. Wei says Jiang is able to “understand what I mean before I finish the sentence”, and Jiang considers his working relationship with Wei as like the chief petty officer and captain on a ship: “He’s the one that makes the decisions and takes the responsibility. My duty is to give him all the advice I have and execute his orders.”

What’s next

Of course, there is no time to rest on success. The company is now moving on to the next stage, which is to develop more customized products for niche markets, as they have sufficient money for R&D. “The industrial implementation is the real deal. We get to decide whether the industrial environment is big or worthy enough to develop a specific model.” Like any start-up that expands after its initial stage, AgileX is transitioning from a highly self-motivated but rough management style to being more systematic. Jiang admits that it is a challenge. “We can’t just copy the way of the large companies, but we can’t stay the same,” he says. “As we expand, management will become more like neurosurgery – you have to give concrete instructions to the right person at the right spot.” These changes are necessary, however, to ramp up the business. Wei is setting up a new office at the University Town of Shenzhen focused on sales and marketing, to be closer to the market. “In Songshan Lake, it takes a lot of effort [to get out here] for those who truly want to do business with you.” Although currently sales are mainly being boosted by “word-of-mouth”, Wei intends to gain more insights on the market in Shenzhen. “It is unavoidable for a company to make mistakes during development, so we need all kinds of information. I’m here to learn in Shenzhen.” As the mainland city which is most closely connected with Hong Kong and Macau, Wei is also expecting more communication and cooperation with the two SARs under the development of the Greater Bay Area plan. “I think it’s definitely a trend for the cities in the Pearl River Delta to cooperate with Hong Kong and Macau,” he says. Wei believes the mainland and Hong Kong should each do the best in their own fields. “Hong Kong is very strong in finance as well as high-end talents, while the Pearl River Delta is good at the industrial implementation and is supply chain.” Good insight. And good advice for aspiring entrepreneurs on both sides of the border.